ANNOUNCEMENT: Frontier buyers sign USD $44.2M multi-year offtake with NULIFE for 122,000 tons of permanent carbon removal. Learn More

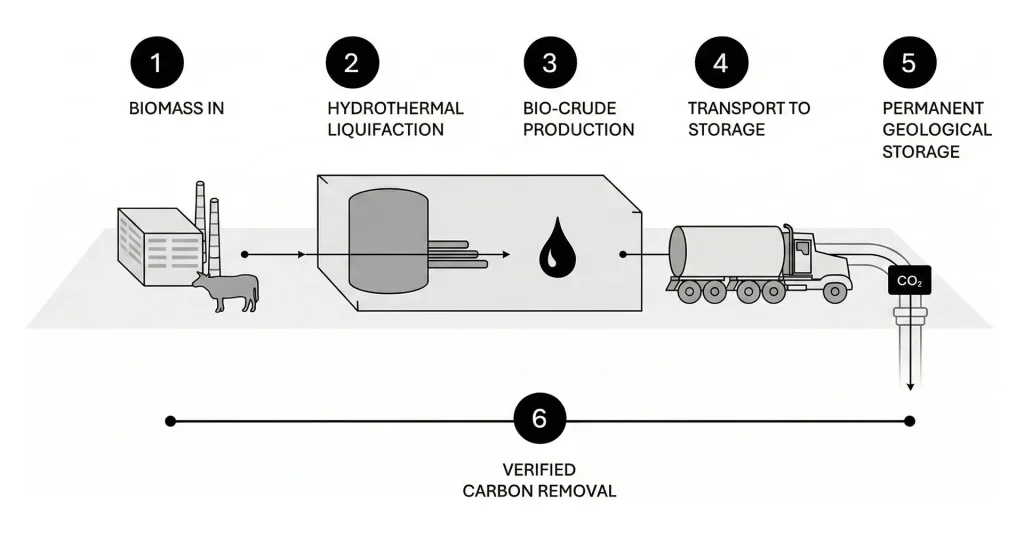

NULIFE GreenTech uses patented hydrothermal liquefaction (HTL) to convert underutilized biomass feedstocks — including organic by-products, crop residues, and waste biomass — into carbon-rich biocrude for permanent geological storage.

This approach is a form of biomass carbon removal and storage (BiCRS): we convert biomass into stable carbon and store it durably underground, delivering engineered carbon removals.

Our HTL system is designed for real-world industrial conditions, handling dry and wet biomass with variable moisture and composition, and producing consistent, high-integrity removals that are independently verified by Isometric.

NULIFE’s HTL technology is powered by electricity and uses approximately 230 kWh of electricity per metric tonne of CO₂ removed—roughly 10x lower than typical direct air capture.

Underutilized biomass feedstocks — such as agricultural, biosolids from wastewater treatment plants, and industrial organics — are pre-screened and prepared for processing. The system is designed to accept dry and wet residuals with variable moisture and composition, often replacing landfilling or land application as the primary waste-management route.

NULIFE’s continuous HTL process breaks down and liquefies high-moisture organic materials. The exothermic reaction occurs under high pressure (2,900 – 3,700 psig) and temperature (290 - 375°C), using water as a catalyst to reform the biomass carbon into long-chain hydrocarbons (biocrude oil). Process by-products include biochar and gaseous carbon dioxide (CO₂).

The resulting biocrude is a pumpable, transportable product with high carbon content and favourable properties for both permanent storage and future upgrading to low-carbon fuels.

Biocrude is transferred to secure storage and transported to compatible geological storage infrastructure, using standard industrial logistics and equipment.

At the storage site, the carbon in the biocrude is permanently sequestered in suitable geological formations, meeting strict durability criteria for engineered carbon removal.

Each step is measured, monitored, and documented so that the net carbon removal can be quantified and independently verified for buyers.

NULIFE’s carbon removals are quantified and independently verified by Isometric, with every tonne of CO₂ stored subject to rigorous measurement, reporting, and verification (MRV).

This gives CDR buyers and regulators confidence that NULIFE’s removals are transparent, durable, and backed by independent oversight rather than self-asserted claims.

In carbon removal, “net negativity” describes how much CO₂ is removed from the atmosphere after accounting for all lifecycle emissions from the project (energy use, equipment, transport, etc.). A pathway that is 100% net-negative would remove CO₂ with effectively no associated emissions; at 0% net-negativity, any stored CO₂ is fully offset by the emissions required to deliver it.

NULIFE’s operational data shows that our current HTL pathway is already delivering over 90% net negativity: for every tonne of CO₂ permanently stored, only a small fraction is re-emitted across the full system boundary. The largest remaining emissions sources are facility electricity use, embodied emissions in equipment, and transportation of biocrude to the injection site.

Many CDR suppliers rely primarily on preliminary, modeled LCAs to characterize net negativity. NULIFE’s figures are grounded in measured operational data from our commercial facility. NULIFE’s net negativity is expected to improve towards 95% as facilities mature and wider energy system decarbonizes.

Biocrude from NULIFE has been successfully upgraded to American Society for Testing and Materials (ASTM)-spec renewable diesel, with a preliminary carbon intensity of –14 g CO₂e/MJ under the British Columbia Low Carbon Fuel Standard GH Genius protocol. Further upgrading validation at a larger scale is underway for pathways such as renewable diesel and Sustainable Aviation Fuel (SAF).

HTL biocrude oil is better for renewable fuel upgrading than pyrolysis bio-oil because it is more stable, has lower oxygen content, higher carbon density, and far less water. This makes NULIFE’s biocrude less expensive to upgrade to low-carbon fuels.

NULIFE’s bio-crude is produced from residual biomass and waste streams, avoiding the food-versus-fuel tradeoffs associated with crops like soybean or canola oil used to traditionally create biodiesel or renewable diesel.

For fuel innovators, this provides early evidence that NULIFE’s technology can support future low-carbon fuels at scale, while today’s focus remains on delivering high-integrity carbon removals.

NULIFE’s modular, electrically-powered HTL units are engineered to integrate into existing industrial environments and sit close to major feedstock sources, and are designed to:

Purchase Verified Removals

Learn how NULIFE provides Isometric-verified, ICVCM-aligned carbon removals with near-term availability, strong environmental co-benefits, and reliable, on-schedule delivery.

Partner on Feedstock Supply

Understand how NULIFE can solve your feedstock management pain points by converting underutilized biomass residuals into high-integrity carbon removals and future low-carbon products.

Low Carbon Fuel Opportunities

Learn about NULIFE’s biocrude specifications and its future renewable fuel pathways, lifecycle carbon intensity results and eligibility under North American clean fuel programs.