ANNOUNCEMENT: Frontier buyers sign USD $44.2M multi-year offtake with NULIFE for 122,000 tons of permanent carbon removal. Learn More

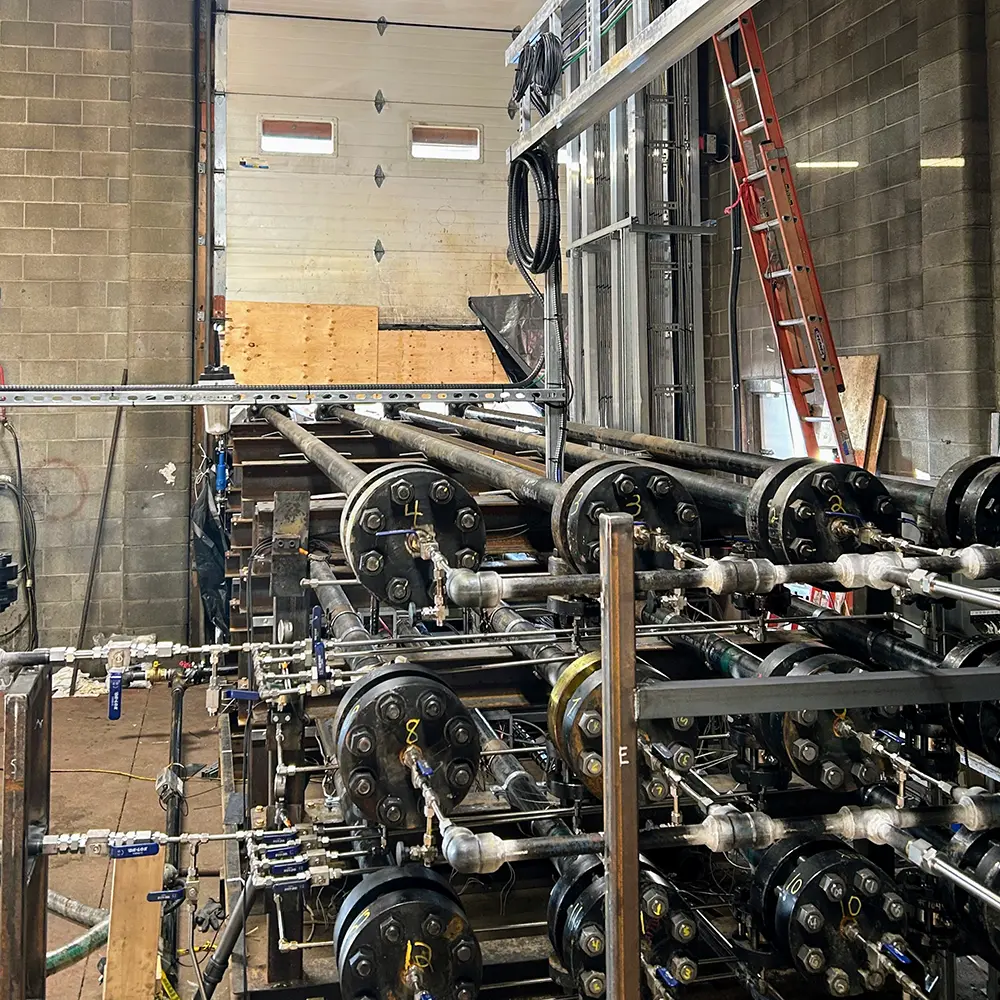

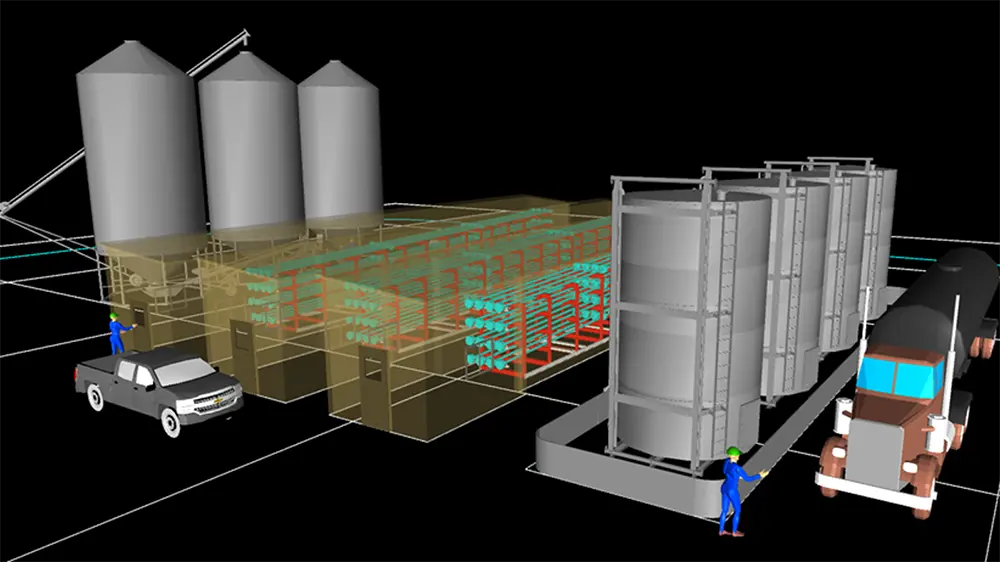

NULIFE’s Saskatoon facility, which as been operational since 2023, is a continuous-flow HTL plant engineered for real-world industrial conditions, processing dry and wet biomass residuals with variable moisture and composition, converting them into dense, storable biocrude for permanent geological storage.

The facility is supplied by regional partners generating biomass residuals such as agricultural by-products and food-processing residues.

2016

Proof of concept HTL reactor successfully demonstrates conversion of biomass to biocrude.

2017 - 2021

2023

2024 - Q1 2025

A second processor is added in 2024, followed by expansion to four commercial-scale processors in Q1 2025.

Q4 2025

Location: Saskatoon, Saskatchewan, Canada

Status: Operational since 2023

Feedstocks: Oat hulls, sludges and other related biomass residues

Size: commercial HTL module

Processing Capacity: ~5,000 dry metric tonnes of biomass per year

CDR Capacity: ~5,000 tCO₂/year

Biocrude Production: ~30 bbl/day

Storage: Geological storage in Saskatchewan

Registry: Isometric – NULIFE GreenTech Ontario Avenue Bio-Oil Sequestration (Registered, Validated and Verified)

Location: Saskatoon, Saskatchewan, Canada

Status: Under development; targeting operations in Q1 2027

Feedstocks: Oat hulls and related grain-processing residuals

Size: 3 commercial HTL modules

Processing Capacity: ~33,000 dry metric tonnes/year

CDR Capacity: ~33,000 tCO₂/year

Biocrude Production: ~250 bbl/day

Storage: Geological storage in Saskatchewan

Registry: Isometric – NULIFE GreenTech Ontario Avenue Bio-Oil Sequestration (Registered, Validated and Verified)

NULIFE will build, own, and operate (BOO) a distributed network of HTL facilities located near major biomass residual hubs. Each future facility will follow the same core principles:

Details and timelines for future facilities will be shared as projects reach appropriate development milestones.

NULIFE’s facilities are designed to work with a range of biomass residuals that are costly and complex to manage through traditional waste routes. Typical feedstocks for the Saskatoon facility include:

Examples:

Examples:

identified through project-specific assessment.

NULIFE’s facilities are sited close to major generators of biomass residuals to simplify logistics and reduce transport costs. Co-location or near-site placement allows residuals to be transferred directly to HTL facilities using standard industrial equipment, rather than trucked to distant landfills or land-application sites.

Each facility is designed around a regional catchment area for qualifying feedstocks, balancing logistics practicality with climate and economic performance. For feedstock partners, this reduces the complexity of waste management and integrates permanent carbon removal into day-to-day operations with minimal disruption.

Whether you are buying removals, generating biomass residuals, or planning future low-carbon infrastructure, NULIFE’s facilities are designed to support long-term, climate-positive partnerships.

Purchase Verified Removals

Learn how NULIFE provides Isometric-verified, ICVCM-aligned carbon removals with near-term availability, strong environmental co-benefits, and reliable, on-schedule delivery.

Partner on Feedstock Supply

Turn biomass residuals from a disposal problem into permanent carbon removal and future low-carbon products.

Low Carbon Fuel Opportunities

Learn about NULIFE’s biocrude specifications and its future renewable fuel pathways, lifecycle carbon intensity results and eligibility under North American clean fuel programs.